기존 제품대비 성능 향상된 최신 국산 신제품 BMS(Battery Monitoring System)

2021. 10 : DR(디지털 리얼리티) 상암동 IDC 센터 비상발전기(지엔씨에너지) BMS 설치

2021. 09 : 수자원공사 지역 수도 사업소 BMS 설치

2021. 01 : 대전 조폐공사 본사 IDC BMS 설치

2020. 12 : 일본 홋가이도 전력 연구소 BMS 납품

2020. 09 : 울릉도 레이더 기지 BMS 설치

2020. 09 : 용산 KT IDC 비상발전기(지엔씨에너지) BMS 설치

2020. 06 : 한전 대전 세종 충남 본부 BMS 설치

2020. 01 : 지필로스 제주 풍력발전 BMS 설치

2019. 04 : 코원 에너지 BMS 설치

2019. 03 : 한전 동해전력지사 BMS 설치

2018. 11 : NH투자증권 BMS 설치

2018. 07 : 한전 광주전남본부 BMS 설치

2018. 05 : 울산화력 발전소 BMS 설치

2017. 12 : 일본 동경전력 지사 BMS 설치

2017. 08 : 평택 포승 파워 발전소 BMS 설치

2017. 06 : 카길 퓨리나 공장 BMS 설치

2016. 11 : 삼성종합기술원 BMS 설치

2016. 11 - 2017. 04 : 한국도로공사 BMS 구축

2016. 03 : 제일의료재단 제일병원 BMS 구축

2015.0 9 - 2018.10 : 현대정보기술 BMS 구축

2015. 06 : 롯데정보통신 가산 IDC BMS 구축

2015. 06 : KLID BMS 구축

2014. 11 : 한국거래소 BMS 설치

2014. 09 : 한국거래소 BMS 설치

2014. 04 : 교통안전공단 BMS 구축

■2볼트 설치 사진

■2볼트 24셀 충전기 설치 사진

■12볼트 설치 사진

|

CellScan Master (Master) |

CS-Sensor (Sensor) |

|||

|

시스템 용량 (System Capability) |

측정 용량 (Measuring Capability) |

|||

|

셀 센서 |

100개 제어 |

LV 센서 |

(2V/4V/6V 용) 모듈 당 최대 4셀 수용 |

|

|

조 전압, 전류 |

각 1개 |

HV 센서 |

(8V/12V 용) 모듈 당 최대 4셀 수용 |

|

|

통신포트 |

CAN 2개 (Ring구성) , Ethernet 1개, RS-232 1개 |

통신포트 |

CAN 2개 (Ring구성) |

|

|

주위온도 |

1개 |

온도센서 |

4개 ( 전체 셀 온도 측정은 옵션 ) |

|

|

측정 속도 (Measuring Speed) |

측정 속도 (Measuring Speed) |

|||

|

조 전압 |

0.1초 |

400개 전체 셀에 대한 개별 전압과 온도측정 |

1초 |

|

|

조 전류 |

0.1초 |

400개 전체 셀에 대한 개별 셀 내부저항 측정 |

회수 설정 가능 |

|

|

측정 범위 및 정확도 (Range & Accuracy) |

측정 범위 및 정확도 (Range & Accuracy) |

|||

|

조 전압 |

0 ~ 1,000VDC / ±0.5% of full scale |

셀 전압 |

0 ~ 9.0V / ±0.1% of ±10mV ( 2V용) |

|

|

조 전류 |

0 ~ 1,000ADC / ±1.0% of full scale |

0 ~ 17.0V / ±0.1% of ±20mV (12V용) |

||

|

조 리플 |

0 ~ 1,000Ap-p / ±5.0% of full scale |

셀 온도 |

-20 ~ +80℃ / ±0.5℃ |

|

|

주위온도 |

- 20 ~ 80℃ / ±0.5℃ |

셀 내부저항 |

0 ~ 100.0mΩ/ ±2.0% of full scale |

|

|

해상도 (Resolution) |

해상도 (Resolution) |

|||

|

조 전압 |

0.1V / 조 전류 : 0.1A |

셀 전압 |

1mV |

|

|

조 리플 |

0.1Ap-p / 주위온도 : 0.1℃ |

셀 온도 |

0.1 ℃ |

|

|

|

셀 내부저항 |

0.001mΩ |

||

|

크기, 동작환경 (Dimensions & Environment) |

크기, 동작환경 (Dimensions & Environment) |

|||

|

크기 |

245 × 170 × 45㎜ |

크기 |

크기: 128 × 61 × 35㎜ |

|

|

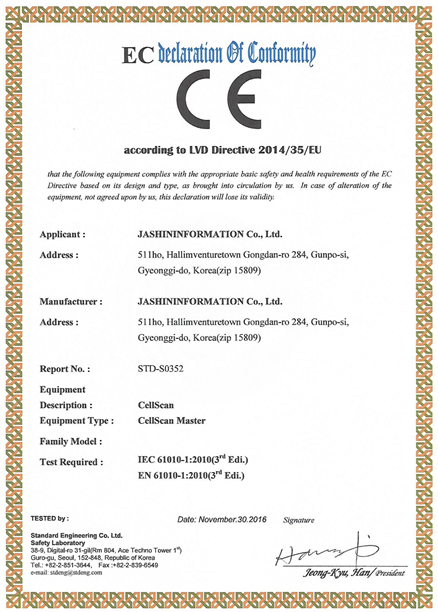

인증, 동작환경 |

CE 온도 : 0 ~ 50 ℃ / 습도 : 80%RH 이하 |

인증, 동작환경 |

CE 온도 : 0 ~ 50 ℃ / 습도 : 80%RH 이하 |

|

|

특징요약 |

• 배터리 조당 1개의 Master 필요 • 1개 Master는 최대 100개의 Sensor 수용하고, • Sensor의 CAN 통신 데이터를 Ethernet 데이터로 • 전원과 시스템 이상, 조전압/조전류/주위온도 |

특징요약 |

• 배터리의 전압에 따라 LV 센서, HV 센서 적용 • CAN통신 케이블이 Ring으로 구성되어 고신뢰도 • CAN ID 표시용 FND가 점멸하면 CAN 통신 이상 • 셀 당 셀 전압, 셀 내부저항 , 셀 온도를 측정 • 셀 전압과 온도(1초), 셀 내부저항(사용자 선택) • CAN ID와 CAN 통신 이상, 셀 이상 시, 표시 |

|

■ CellScan Master

▶ 측정 데이터 : 조 전압, 조 전류, 주위온도, 리플 전류

▶ 측정 주기 : 0.1sec

▶ 표시

- 전원 및 시스템 이상

- 조전압 / 조전류 / 주위온도 이상

- 셀 전압 / 셀 온도 / 셀 내부저항 이상

- 사용자 알람 지정 (6EA)

■ CellScan Sensor

▶ 측정 데이터 : 셀 전압, 셀 내부저항, 셀 온도

▶ 측정 주기 : 셀 전압 및 셀 온도 : 1sec

셀 내부저항 : 사용자 선택 (설정 가능)

▶ 표시

- CAN ID 및 CAN 통신 이상

- CAN ID 표시용 FND가 점멸하면 CAN 통신 이상

- 셀 측정 데이터 이상

▶ 측정된 데이터는 분석 프로그램 CellScan 소프트웨어를 통해 실시간으로 확인

▶ CellScan에서 관리하는 모든 배터리 조의 통계 정보 제공

▶ 알람 실시간 관리 및 이력 정보 제공

▶ 방전 실시간 관리 및 이력정보 / 방전 리플레이 기능 제공

▶ 충/방전 전류의 리플 전류값 제공 및 고속 퓨리에 변환 기술로 리플전류 파형기록

▶ 엑셀 및 PDF 파일 출력 및 보고서 출력 기능 제공

▶ e-mail 및 SMS 전송 기능 제공 / 상위시스템 연동을 위한 SNMP 프로토콜 수용 (옵션)

▶ CAN (Controller Area Network) 방식으로 측정속도가 매우 빠름

▶ 고속 샘플링 기능으로 순간 정전 (0.5초 이하) 이벤트 기록 가능

▶ 방전 시 각 셀에 대한 셀 전압 매 초 동시 측정

▶ 충전 리플 전류 측정 및 FFT 분석

▶ 납 축전지에 대한 점검기준인 IEEE 1188-2005, IEEE 450 권고기준에 적합한 제품

▶ 각 셀/모듈에 대한 전압, 온도, 내부저항을 상시 측정하는 제품

▶ 설치와 관리가 용이한 표준 CAN 2선 공통 링-버스 통신방식 케이블 사용

▶ 400셀 전체에 대한 측정시간이 매우 빠름 (전압과 온도 총 측정시간 1초 이내)